Продавец оборудования для бизнеса

ООО (организация)

Телефон

Киевская область

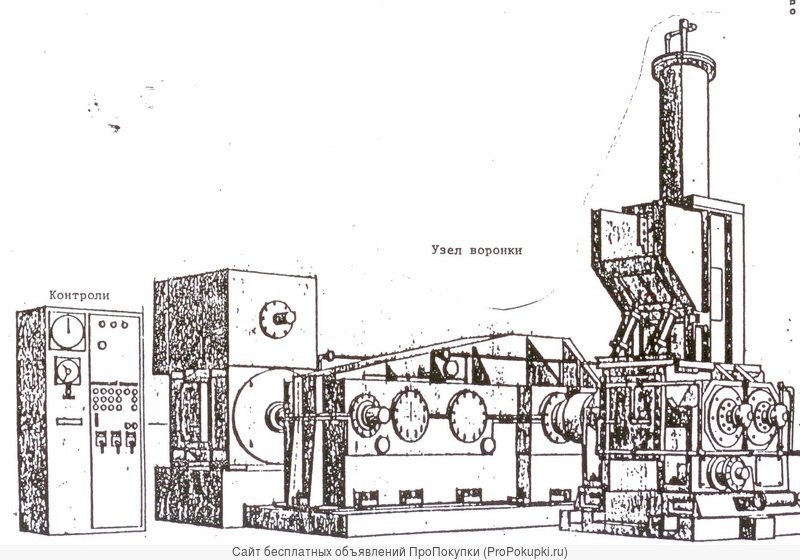

Основные характеристики резиносмесителя: РС-250/30

1.Свободный объем смесительной камеры, дм.куб

2.Коэффициент загрузки смесительной камеры

3.Среднее время перемешивания, мин

4.Частота вращения ротора, об/мин

- заднего

- переднего

5.Фрикция

6.Давление сжатого воздуха, мПа

7.Давление на смесь, Мпа

8.Охлаждающая вода: - давление, Мпа

- расход, м.куб/час

9.Расход воды на охлаждение эл. двигателя, м.куб/час

10.Эл. двигатель главного привода: тип

- напряжение, В

- мощность, кВт

- частота вращения, об/мин

11.Эл. двигатель вентилятора главного привода: - тип

- напряжение, В

- мощность, кВт

12.Эл. двигатель насоса смазки:

13.Габаритные размеры: - длина, мм

- ширина, мм

- высота, мм

14.Масса с приводом, тонн

250

0.50 – 0.85

5 – 7

30

25,0

1 : 1.18

0.6 – 0.8

0.66

0.4

23

13

СДРЗ-14-59-8

6000

630

750

АОЛ2-21/4

220/380

1.1 х 2

АО-42-4

7800

4400

5900

64.000

TPP HIMMASHEXPORT LTD has all facilities to manufacture and supply:

1.Spare parts to internal rubber mixers, calendering machines, roll mills, extrusion machines, in particular: mixing chambers, rotors(weld neck bushings, rotor seals), reduction gear assembly, speed reduction device SHM-250, KC-60, KC-50, KC-70, CO-70, CO-75, CO-80, BSM and etc., shafts, spline shafts, spline bushings, couplers, gear wheels, circular tooth gear wheels, helical tooth gear wheels, friction gear wheels, drive gear wheels, gear shaft, tooth-wheels, sheave wheels, tread bands, bushings, sleeves, bed plates (moulded, welded).

2. Hobs for extrusion machineswith length of threaded part up to 2500 mm, with diameter up to 400 mm, (warm type extrusion machine, cold type extrusion machine, hot type extrusion machine,cold typeextrusion machines assembly unit, grainers, strainer extruders) of complex form, single-thread, multiple-thread, withvariable pitch and diameter, with adjustable pitch and form according to zones, sleeves and etc.

3. Calender linescompleted with automated control system based onindustrial computers.

4.Rolls to calendering machines, rolls with inner barrel for cooling and rolling with marginal drilling for cooling. Roll mills, units with 2 and 3 roll mills.Laboratory roll mills.

5. Internal rubber mixers lines based on internal rubber mixers RS-270, 250, 90, 71equipped with update ingredients dispensing and compound rubber cooling system (festoon-type cooling plant)

6. Bases, vaporizing chambers, speed reducing devices with down and vertical travel, other spare parts to shaper vulcanizers.

7. Castings for spare parts and rotors tointernal rubber mixers RS-270, 250, 90, 71, RSVD-140are made according to new European cast technology –using forms out of coldconsolidating mixtures (CCM), which enables to gain cast precision class 8-13, in complex geometry forms with precision 1 mm., high quality of surface smoothness and low grade of casting defects. Forms and pins are made at forming line of preparing self-hardening mixtures by OMEGA company(England) according to cold-box furan process technology. Starting material as well as finished products are subjects to laboratory testing (via spectrometer SOLARIS CCD Plus, Italy)which secures obtaining of moulds with one-to-one correspondence of targeted microstructural and chemical composition of product.

8. We also supply assembly units as well as spare parts to enterprises of such spheres: rubber technical industry, cable manufacturers, tires manufacturers, asbestos technological companies, hydropower plants, heat and power stations, mining and processing complexes. Utilization of manufactured equipment in chemical, petrochemical, metallurgical, mining and ore mining, oil and gas extraction, building and many other industry fields.

1.Свободный объем смесительной камеры, дм.куб

2.Коэффициент загрузки смесительной камеры

3.Среднее время перемешивания, мин

4.Частота вращения ротора, об/мин

- заднего

- переднего

5.Фрикция

6.Давление сжатого воздуха, мПа

7.Давление на смесь, Мпа

8.Охлаждающая вода: - давление, Мпа

- расход, м.куб/час

9.Расход воды на охлаждение эл. двигателя, м.куб/час

10.Эл. двигатель главного привода: тип

- напряжение, В

- мощность, кВт

- частота вращения, об/мин

11.Эл. двигатель вентилятора главного привода: - тип

- напряжение, В

- мощность, кВт

12.Эл. двигатель насоса смазки:

13.Габаритные размеры: - длина, мм

- ширина, мм

- высота, мм

14.Масса с приводом, тонн

250

0.50 – 0.85

5 – 7

30

25,0

1 : 1.18

0.6 – 0.8

0.66

0.4

23

13

СДРЗ-14-59-8

6000

630

750

АОЛ2-21/4

220/380

1.1 х 2

АО-42-4

7800

4400

5900

64.000

TPP HIMMASHEXPORT LTD has all facilities to manufacture and supply:

1.Spare parts to internal rubber mixers, calendering machines, roll mills, extrusion machines, in particular: mixing chambers, rotors(weld neck bushings, rotor seals), reduction gear assembly, speed reduction device SHM-250, KC-60, KC-50, KC-70, CO-70, CO-75, CO-80, BSM and etc., shafts, spline shafts, spline bushings, couplers, gear wheels, circular tooth gear wheels, helical tooth gear wheels, friction gear wheels, drive gear wheels, gear shaft, tooth-wheels, sheave wheels, tread bands, bushings, sleeves, bed plates (moulded, welded).

2. Hobs for extrusion machineswith length of threaded part up to 2500 mm, with diameter up to 400 mm, (warm type extrusion machine, cold type extrusion machine, hot type extrusion machine,cold typeextrusion machines assembly unit, grainers, strainer extruders) of complex form, single-thread, multiple-thread, withvariable pitch and diameter, with adjustable pitch and form according to zones, sleeves and etc.

3. Calender linescompleted with automated control system based onindustrial computers.

4.Rolls to calendering machines, rolls with inner barrel for cooling and rolling with marginal drilling for cooling. Roll mills, units with 2 and 3 roll mills.Laboratory roll mills.

5. Internal rubber mixers lines based on internal rubber mixers RS-270, 250, 90, 71equipped with update ingredients dispensing and compound rubber cooling system (festoon-type cooling plant)

6. Bases, vaporizing chambers, speed reducing devices with down and vertical travel, other spare parts to shaper vulcanizers.

7. Castings for spare parts and rotors tointernal rubber mixers RS-270, 250, 90, 71, RSVD-140are made according to new European cast technology –using forms out of coldconsolidating mixtures (CCM), which enables to gain cast precision class 8-13, in complex geometry forms with precision 1 mm., high quality of surface smoothness and low grade of casting defects. Forms and pins are made at forming line of preparing self-hardening mixtures by OMEGA company(England) according to cold-box furan process technology. Starting material as well as finished products are subjects to laboratory testing (via spectrometer SOLARIS CCD Plus, Italy)which secures obtaining of moulds with one-to-one correspondence of targeted microstructural and chemical composition of product.

8. We also supply assembly units as well as spare parts to enterprises of such spheres: rubber technical industry, cable manufacturers, tires manufacturers, asbestos technological companies, hydropower plants, heat and power stations, mining and processing complexes. Utilization of manufactured equipment in chemical, petrochemical, metallurgical, mining and ore mining, oil and gas extraction, building and many other industry fields.

| Классификация |

| вид: производственное оборудование |

| условия: продажа |